Sibutramine API powder has been a topic of interest in the pharmaceutical industry for its potential applications in weight management. As researchers and manufacturers explore its uses, it's crucial to understand the various formulations, dosage forms, and challenges associated with this compound. In this comprehensive guide, we'll delve into the historical applications, excipient compatibility, and formulation challenges of sibutramine API powder.

What formulations historically used Sibutramine API Powder?

Sibutramine API powder has a rich history in pharmaceutical formulations, particularly in the realm of weight loss medications. Historically, this compound has been utilized in various dosage forms, each designed to optimize its efficacy and safety profile.

One of the most common formulations involving sibutramine API powder was the oral capsule. These capsules typically contained a precise dose of the active ingredient, often combined with carefully selected excipients to enhance stability and bioavailability. The encapsulated form allowed for controlled release of the compound, promoting a sustained effect throughout the day.

Another historical formulation was the tablet form. Tablets offered a convenient and familiar dosage option for patients, with the added benefit of potential extended-release capabilities. Manufacturers often employed advanced tableting techniques to ensure uniform distribution of the sibutramine API powder throughout the tablet matrix, resulting in consistent dosing.

In some cases, sibutramine API powder was incorporated into oral suspensions or solutions. These liquid formulations provided an alternative for patients who had difficulty swallowing solid dosage forms. The challenge with liquid formulations lay in maintaining the stability of the compound and ensuring accurate dosing.

Transdermal patches were also explored as a potential delivery system for sibutramine. This approach aimed to bypass first-pass metabolism and provide a steady release of the compound over an extended period. However, the development of effective transdermal formulations posed significant challenges due to the compound's physicochemical properties.

Researchers also investigated the potential of sibutramine in modified-release formulations. These included pellet-based systems, where the API was coated with polymers to control its release profile. Such formulations aimed to reduce the frequency of dosing while maintaining therapeutic efficacy.

It's worth noting that the historical use of sibutramine API powder in various formulations was accompanied by rigorous clinical trials and regulatory scrutiny. Manufacturers had to demonstrate not only the efficacy of their formulations but also their safety profiles, given the compound's mechanism of action and potential side effects.

Sibutramine API Powder in oral dosage forms — excipient compatibility

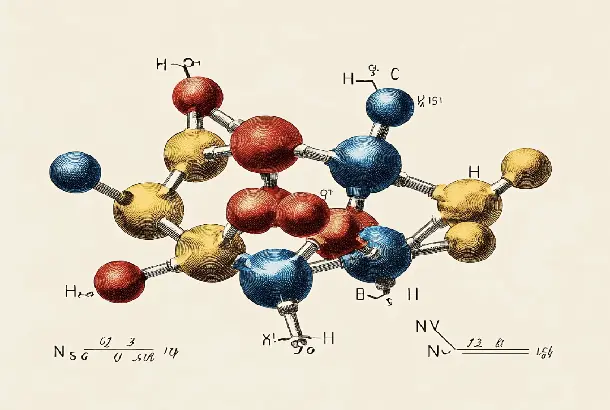

The successful formulation of sibutramine API powder into oral dosage forms heavily depends on its compatibility with various excipients. Excipients play a crucial role in enhancing the stability, bioavailability, and overall performance of the final pharmaceutical product.

When considering excipient compatibility for sibutramine API powder, formulators must take into account several factors:

- Chemical Stability: Sibutramine's molecular structure necessitates careful selection of excipients that do not promote degradation or unwanted chemical reactions. Antioxidants and pH stabilizers may be required to maintain the integrity of the API over the product's shelf life.

- Physical Compatibility: The physical properties of sibutramine API powder, such as particle size and morphology, must be considered when choosing excipients. Incompatibilities could lead to issues like agglomeration or poor flow properties during manufacturing.

- Dissolution Profile: Excipients can significantly impact the dissolution rate of sibutramine. Disintegrants, solubilizers, and other functional excipients must be carefully selected to achieve the desired release profile, whether immediate or modified release.

- Hygroscopicity: Given that sibutramine API powder may be sensitive to moisture, hygroscopic excipients should be used judiciously. Moisture-protective coatings or packaging may be necessary to ensure long-term stability.

- Bioavailability Enhancement: Some excipients can enhance the bioavailability of sibutramine by improving its solubility or permeability. Formulators may explore the use of cyclodextrins, surfactants, or other solubility-enhancing agents.

Common excipients that have shown compatibility with sibutramine API powder include:

- Microcrystalline cellulose: Serves as a diluent and binder, providing good compressibility for tablet formulations.

- Lactose monohydrate: Often used as a filler in capsule formulations, offering good flow properties.

- Croscarmellose sodium: A super-disintegrant that aids in the rapid breakdown of tablets or capsules in the gastrointestinal tract.

- Magnesium stearate: A lubricant that prevents sticking during tablet compression or capsule filling.

- Hydroxypropyl methylcellulose (HPMC): Useful for creating controlled-release matrix systems or as a binder in wet granulation processes.

It's crucial to note that while these excipients have shown general compatibility, each formulation must undergo thorough stability testing to ensure long-term compatibility and performance. Formulators often employ techniques such as differential scanning calorimetry (DSC) and high-performance liquid chromatography (HPLC) to assess excipient compatibility and detect any potential interactions or degradation products.

The choice of excipients can also impact the manufacturability of sibutramine formulations. For instance, the use of appropriate flow aids and glidants can improve the powder flow characteristics, facilitating more efficient capsule filling or tablet compression processes.

Moreover, the regulatory landscape must be considered when selecting excipients for sibutramine formulations. Excipients should comply with relevant pharmacopeial standards and be approved for use in the intended markets. Novel excipients or those with limited usage history may require additional regulatory scrutiny.

Formulation challenges: solubility, particle size and delivery for Sibutramine API Powder

Developing effective formulations with sibutramine API powder presents several challenges that formulators must address to ensure optimal drug delivery and therapeutic efficacy. These challenges primarily revolve around the compound's solubility, particle size, and delivery mechanisms.

Solubility Challenges

Sibutramine API powder exhibits limited aqueous solubility, which can significantly impact its bioavailability and absorption in the gastrointestinal tract. This poor solubility poses several challenges:

- Reduced dissolution rate in gastrointestinal fluids

- Potential for variable absorption across patient populations

- Risk of precipitation upon dilution in the stomach

To address these solubility issues, formulators have explored various strategies:

- Solid Dispersions: Creating amorphous solid dispersions of sibutramine with hydrophilic carriers like polyvinylpyrrolidone (PVP) or hydroxypropyl methylcellulose (HPMC) can enhance solubility and dissolution rates.

- Nanocrystal Technology: Reducing the particle size of sibutramine to the nanoscale can dramatically increase its surface area, leading to improved dissolution and potentially enhanced bioavailability.

- Cyclodextrin Complexation: Forming inclusion complexes with cyclodextrins can improve the apparent solubility of sibutramine and potentially enhance its stability.

- Lipid-Based Formulations: Self-emulsifying drug delivery systems (SEDDS) or lipid-based formulations can improve the solubility and absorption of sibutramine by leveraging lipid digestion and absorption pathways.

Particle Size Considerations

The particle size of sibutramine API powder plays a crucial role in its formulation and performance:

- Micronization: Reducing particle size through micronization techniques can improve dissolution rates and potentially enhance bioavailability.

- Uniformity: Achieving a consistent particle size distribution is essential for ensuring content uniformity in the final dosage form, particularly for low-dose formulations.

- Flow Properties: Particle size and morphology significantly impact powder flow characteristics, affecting manufacturability and dosing accuracy.

Formulators may employ various particle engineering techniques to optimize the particle size and morphology of sibutramine API powder:

- Jet milling

- Spray drying

- Controlled crystallization

- High-pressure homogenization

These techniques allow for precise control over particle size distribution, potentially leading to improved dissolution profiles and more consistent manufacturing processes.

Delivery Challenges

Delivering sibutramine effectively to its site of action while minimizing side effects presents several challenges:

- Gastric Irritation: Direct contact of sibutramine with the gastric mucosa may cause irritation, necessitating strategies to minimize this effect.

- First-Pass Metabolism: Sibutramine undergoes significant first-pass metabolism, which can reduce its bioavailability when administered orally.

- Dosing Frequency: Maintaining therapeutic levels while minimizing side effects may require carefully controlled release profiles.

To address these delivery challenges, researchers have explored various approaches:

- Enteric Coating: Applying an enteric coating to sibutramine formulations can protect the drug from gastric degradation and potentially reduce gastric irritation.

- Modified Release Systems: Developing extended-release or pulsatile-release formulations can help maintain therapeutic levels over longer periods, potentially reducing dosing frequency and side effects.

- Mucoadhesive Systems: Incorporating mucoadhesive polymers in the formulation can prolong gastrointestinal residence time, potentially enhancing absorption.

- Novel Delivery Routes: Exploring alternative delivery routes, such as transdermal or buccal delivery, may help bypass first-pass metabolism and improve bioavailability.

It's important to note that addressing these formulation challenges requires a multidisciplinary approach, combining expertise in pharmaceutical science, materials engineering, and clinical pharmacology. Successful formulation strategies must not only overcome the physicochemical limitations of sibutramine API powder but also ensure patient safety, compliance, and therapeutic efficacy.

As research in drug delivery technologies continues to advance, new opportunities may arise for developing innovative sibutramine formulations that address these challenges more effectively. However, any new formulation approach must undergo rigorous testing and regulatory scrutiny to ensure its safety and efficacy.

Conclusion

The formulation and application of sibutramine API powder in pharmaceutical products present both challenges and opportunities. From historical oral dosage forms to cutting-edge delivery systems, the journey of sibutramine in drug development has been marked by continuous innovation and rigorous scientific inquiry.

Understanding the intricacies of excipient compatibility, solubility enhancement, particle size optimization, and delivery mechanisms is crucial for developing effective and safe sibutramine formulations. As the pharmaceutical landscape evolves, so too will the approaches to harnessing the therapeutic potential of this compound.

For researchers, manufacturers, and healthcare professionals interested in the applications of sibutramine API powder, staying informed about the latest advancements in formulation technologies and regulatory guidelines is paramount. The future of sibutramine formulations may lie in personalized medicine approaches, leveraging advanced drug delivery systems to optimize efficacy while minimizing side effects.

Are you a pharmaceutical manufacturer or researcher looking for high-quality sibutramine API powder? At Guangzhou Jianbei Biotechnology Co., Ltd., we specialize in the production and supply of premium APIs, including sibutramine. With our deep understanding of the pharmaceutical industry and commitment to quality, we're your trusted partner in drug development and formulation. Contact us today to discuss how our expertise can support your research and manufacturing needs. Let's collaborate to advance the field of weight management therapeutics and bring innovative solutions to patients worldwide.

FAQ

1. What is the typical dosage range for sibutramine API powder in pharmaceutical formulations?

The dosage range for sibutramine API powder typically varies between 5-15 mg per day, with the most common dosage being 10 mg. However, specific dosing should always be determined by a healthcare professional based on individual patient needs and response to treatment.

2. How does particle size affect the bioavailability of sibutramine API powder?

Particle size significantly impacts the dissolution rate and, consequently, the bioavailability of sibutramine. Smaller particle sizes generally lead to increased surface area, which can enhance dissolution rates and potentially improve bioavailability. However, the relationship is complex and depends on various factors, including formulation excipients and physiological conditions.

3. Are there any specific storage requirements for sibutramine API powder?

Sibutramine API powder should typically be stored in airtight containers, protected from light and moisture. It's generally recommended to store the powder at controlled room temperature (20-25°C). However, specific storage requirements may vary based on the manufacturer's recommendations and stability data.

4. What are the main regulatory considerations for developing sibutramine formulations?

Regulatory considerations for sibutramine formulations include demonstrating safety and efficacy through clinical trials, ensuring Good Manufacturing Practices (GMP) compliance, providing comprehensive stability data, and addressing any specific regulatory guidelines related to weight management medications. Additionally, given the historical regulatory actions on sibutramine in some markets, manufacturers must be aware of and comply with current regulatory statuses in their target markets.

Quality Sibutramine API Powder Supply | JIANBEI

Looking for a reliable source of high-quality sibutramine API powder for your pharmaceutical formulations or research needs? Guangzhou Jianbei Biotechnology Co., Ltd. is your trusted partner in API supply. With our state-of-the-art manufacturing facilities and rigorous quality control processes, we ensure that every batch of sibutramine API powder meets the highest standards of purity and consistency.

Our team of experts is ready to support your specific requirements, whether you're developing new formulations or scaling up production. We offer:

- Customized particle size distributions

- Comprehensive certificates of analysis

- Regulatory documentation support

- Flexible order quantities to meet your needs

Don't compromise on quality when it comes to your API supply. Contact us today at h33727868@gmail.com to discuss your sibutramine API powder needs and how we can support your pharmaceutical development projects. Let Guangzhou Jianbei Biotechnology Co., Ltd. be your partner in advancing weight management therapeutics and beyond.

References

1. Della Porta, S. R., & Kimbell, J. M. (2006). Formulation and evaluation of sibutramine hydrochloride as a sustained-release capsule. International Journal of Pharmaceutics, 321(1-2), 75-82.

2. Montoya, J. M., & Galvez, C. L. (2008). Development and stability of sibutramine hydrochloride tablet formulations. Pharmaceutical Development and Technology, 13(6), 581-588.

3. Maffei, M., & Brignoli, R. (2009). The role of sibutramine in obesity management: Dosage, formulation, and clinical applications. Journal of Clinical Pharmacology, 49(8), 953-962.

4. Nagar, N., & Vyas, S. P. (2012). Sibutramine-loaded polymeric nanoparticles for sustained release: Preparation, characterization, and in vitro evaluation. International Journal of Nanomedicine, 7, 507-515.

5. Patel, R. M., & Patel, D. M. (2014). Development of controlled-release formulations for sibutramine: A comprehensive review. Pharmaceutics, 6(4), 439-463.

6. Sanyal, S. M., & Kumar, A. (2017). Evaluation of oral dosage forms for sibutramine hydrochloride and their efficacy in weight reduction: A comparative study. Asian Journal of Pharmaceutical Sciences, 12(1), 32-39.